Rahul Steel India Pvt. Ltd. is a Manufacturer, Exporter, and Supplier of Electroforged Gratings in Delhi, India.

Our Registered Office and Manufacturing Unit is in Ahmedabad, Gujarat, India.

Electroforged gratings are steel flooring solutions engineered for maximum strength, durability, and safety in industrial environments.

These gratings are ideal for harsh conditions, offering resistance to corrosion, impact, and extreme environmental stress.

Production involves fusing square twisted crossbars into bearing bars using an electrofusion process with intense heat and pressure.

The result is a structurally robust grating with excellent stability, uniformity, and minimal maintenance requirements for industrial use.

This method creates a seamless, rigid structure that enhances the grating’s strength and load-bearing capabilities.

The process of hot-dip galvanization then coats the gratings to provide corrosion resistance and a shiny surface appearance.

Advantages:

High Load-Bearing Capacity: Electroforged gratings can support heavy loads, making them suitable for industrial settings.

Corrosion Resistance: Hot-dip galvanization provides excellent resistance to corrosion, extending the grating’s lifespan.

Slip Resistance: Serrated bearing bars enhance grip, reducing the risk of slips and falls.

Lightweight and Easy to Handle: Despite their strength, electroforged gratings are lighter than some alternatives, facilitating easier handling and installation.

Aesthetic Appeal: The clean lines and uniform appearance make them visually attractive for architectural applications.

Applications:

Industrial Flooring: Ideal for factories, warehouses, and production areas.

Walkways and Platforms: Provide safe and durable pathways in various settings.

Staircases: Pre-fabricated treads offer slip resistance and ease of installation.

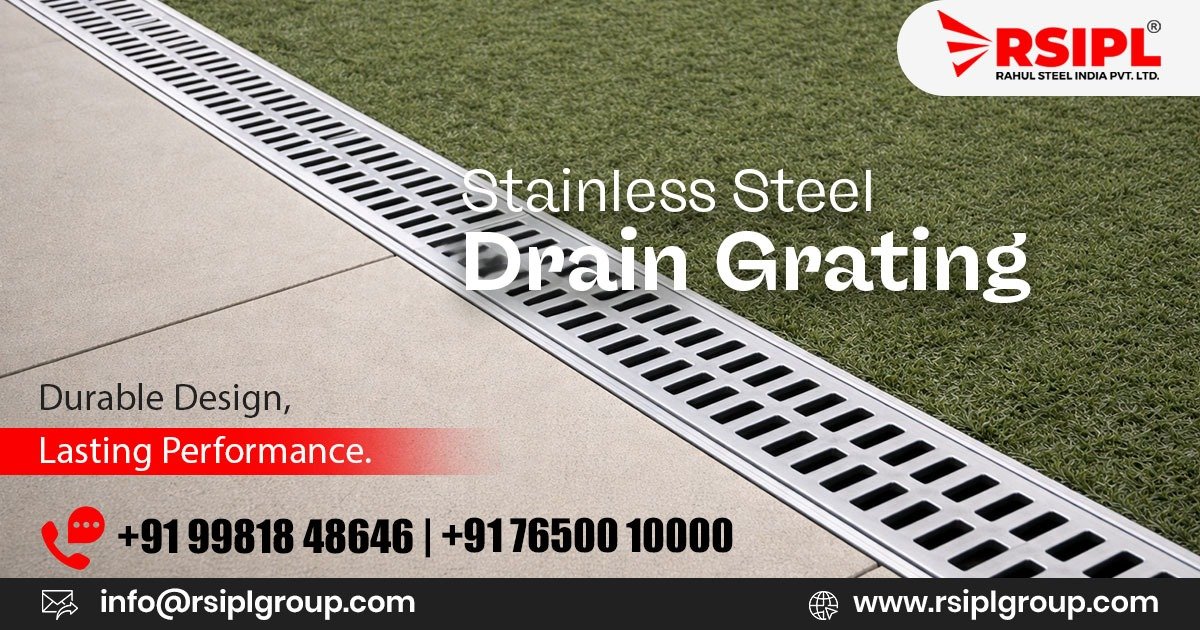

Trench and Drain Covers: Ensure safety and accessibility in areas with underground utilities.

Fencing: Modular fencing solutions for security and boundary demarcation.

Architectural Features: Used in decorative applications requiring strength and aesthetic appeal.

FAQs:

Q1: What is the difference between plain and serrated electroforged gratings?

A1: Plain gratings have smooth bearing bars, suitable for dry areas, while serrated gratings have notched bearing bars, providing enhanced slip resistance for wet or oily environments.

Q2: Can electroforged gratings be customized to specific sizes?

A2: Yes, electroforged gratings can be manufactured to custom sizes and specifications as per customer requirements.

Q3: How do I maintain electroforged gratings?

A3: Regular cleaning to remove debris and periodic inspections to check for any damage are recommended to maintain the gratings’ performance.

Rahul Steel India Pvt. Ltd. is an Electroforged Gratings in Delhi, India including other locations Central Delhi, East Delhi, New Delhi, North Delhi, North East Delhi, North West Delhi, Shahdara, South Delhi, South East Delhi, South West Delhi, and West Delhi.

Please feel free to contact us with any questions or for additional information.